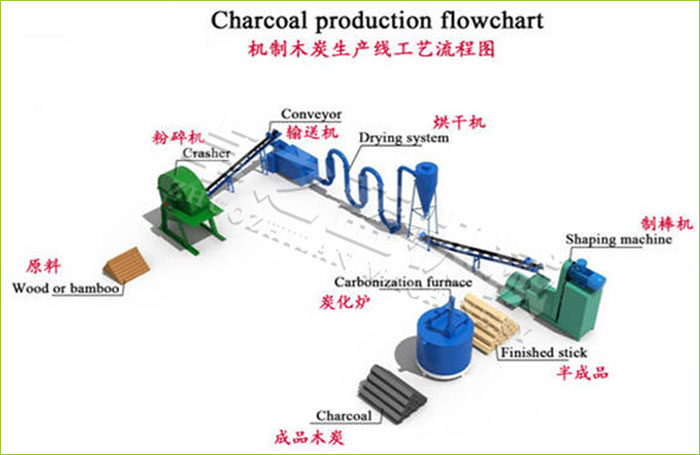

The charcoal briquette manufacturing process mainly includes:material preparation,carbonizing, mixing, briquettes, drying.The charcoal briquette manufacturing process is simple yet effective. It helps reduce waste and provides a sustainable energy source. The charcoal briquette making machine processes materials like sawdust, wood chips, and agricultural residues. Below, we break down the process step by step.

Charcoal Briquette Manufacturing Process

Step 1: Selecting the Raw Materials

The first step involves selecting the right raw materials. Commonly used materials include wood chips, sawdust, and other biomass waste. These materials are rich in carbon, which is essential for producing high-quality charcoal.

After selecting the materials, workers dry them to remove moisture. Wet materials can affect the quality of the final product. Drying usually takes place in a large oven or under the sun.

Step 2: Carbonizing the Materials

The next step is carbonization. This process heats the materials in the absence of oxygen, turning them into charcoal. Carbonization removes volatile compounds and moisture.

Workers perform carbonization in a large kiln or retort. The temperature inside can reach up to 600°C (1112°F). The process takes several hours, depending on the amount of material.

Step 3: Crushing and Mixing

After carbonization, workers crush the materials into a fine powder. They then mix the powder with a binder to help the briquettes hold their shape. Common binders include starch, clay, or molasses.

Workers thoroughly blend the mixture to ensure the binder distributes evenly. This step is crucial for the quality and durability of the final product.

Step 4: Briquetting the Mixture

The next step is briquetting. Here, the iron briquette machine compresses the mixture into the desired shape and size. The machine applies high pressure to ensure the briquettes are compact and durable.

The iron briquette machine handles large volumes of material efficiently. It produces briquettes in various shapes, including round, square, and pillow-shaped. Its efficiency and durability make it essential for the charcoal manufacturing process.

Step 5: Drying the Briquettes

After briquetting, workers dry the charcoal briquettes to remove any remaining moisture. Drying helps the briquettes harden. This step usually takes place in a drying oven or under the sun.

The drying process can take several hours to a few days, depending on humidity and temperature. Proper drying ensures the briquettes burn efficiently and produce less smoke.

Key Charcoal Briquette Making Machine

The charcoal briquette making machine plays a vital role in the process. It compresses charcoal powder or biomass materials into solid briquettes. These briquettes are uniform in shape and size, making them easy to store, transport, and use. The charcoal briquette machine uses high pressure and binders to transform loose materials into dense, compact briquettes.

Another key piece of equipment is the charcoal carbonization furnace. It heats biomass materials in the absence of oxygen, removing moisture and volatile compounds. This process leaves behind pure carbon in the form of charcoal. The furnace operates at high temperatures, typically between 400°C and 600°C (752°F to 1112°F).

The charcoal carbonization furnace is efficient, eco-friendly, and capable of processing large volumes of material. It works well with wood, coconut shells, bamboo, and other biomass waste.

Conclusion

In conclusion, the charcoal carbonization briquette production line is a powerful and eco-friendly solution for producing high-quality charcoal. It efficiently converts biomass waste into valuable fuel, reducing environmental pollution and providing a sustainable energy source. With its advanced features like high thermal efficiency and emission control, this production line is a reliable choice for both small and large-scale operations.

By investing in a charcoal carbonization briquette production line, you not only save costs but also contribute to a greener future. Whether for industrial use or household fuel, this machine delivers consistent performance and durability.

We hope this guide has been helpful! If you have any questions or insights, feel free to leave a comment below. Don’t forget to share this blog on your social media platforms to spread the word about sustainable energy solutions!