What is a Continuous Carbonization Furnace?

Continuous Carbonization Furnace is an advanced machine designed to convert organic materials into carbon without interruption. Unlike traditional batch furnaces, this system operates non-stop, ensuring higher productivity and efficiency. It is widely used in industries like agriculture, energy, and waste management to produce charcoal, biochar, and other carbon-based products.

What is the Continuous Carbonization Process?

The continuous carbonization process involves three main stages:

- Feeding: Raw materials like wood, coconut shells, or agricultural waste are continuously fed into the furnace. This ensures a steady flow of materials for processing.

- Heating: The materials are heated to high temperatures (150°C to 700°C) in an oxygen-free environment. This prevents combustion and breaks down the materials into carbon and byproducts.

- Discharge: The carbonized products are continuously discharged, while byproducts like syngas are collected for reuse. This creates a seamless and efficient production cycle.

The carbonization process is fully automated, reducing labor costs and improving consistency.

How Efficient Are Continuous Carbonization Furnaces?

Continuous Carbonization Furnace Design

Compared with traditional intermittent carbonization furnace, the continuous carbonization furnace design pays more attention to energy saving and consumption reduction;

In the continuous carbonization furnace, a double-layer structure is adopted, that is, a stainless steel furnace body is built in and an insulation material is wrapped outside. This design not only ensures the stability of the high temperature environment inside the carbonization furnace, but also minimizes the heat loss;

At the same time, in the continuous carbonization furnace flue gas emission system,a waste heat recovery device is equipped, which can recycle the waste heat in the flue gas and further improve the energy utilization efficiency;

The introduction of these designs enables the continuous carbonization furnace to save energy and reduce consumption during the entire carbonization process, and complete the entire process in one go.

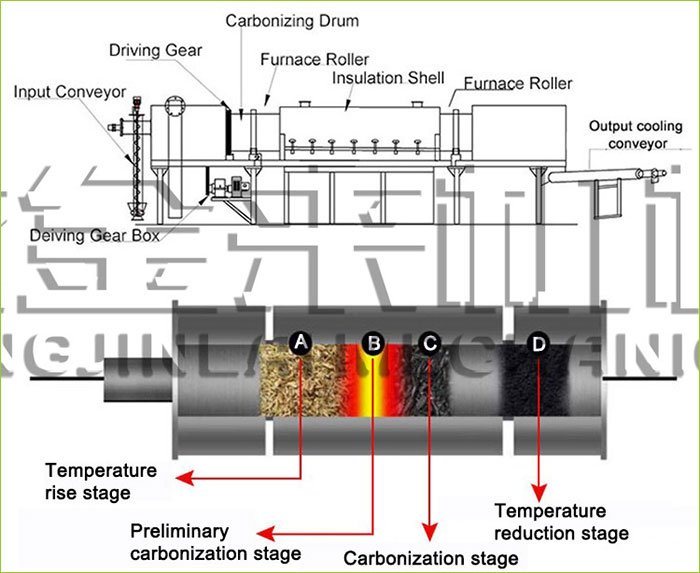

Continuous Carbonization Furnace Working Principle

The continuous carbonization furnace efficiency lies in the optimization of its working principle. The traditional carbonization method generally requires the material to be processed to be put into the carbonization furnace in multiple times, wait for the carbonization reaction to be completed after each time, and then clean it out for the next cycle. The continuous carbonization furnace is designed to realize the functions of continuous feeding, carbonization and discharging, so that the entire carbonization process does not need to be interrupted, thereby improving the carbonization efficiency.

Carbonization Furnace Benifits

Continuous Carbonization Furnaces offer unmatched efficiency and sustainability. They operate non-stop, ensuring high productivity and consistent output. By converting waste materials like wood, coconut shells, and agricultural residues into valuable carbon products, they reduce waste and promote a circular economy. Their heat recovery systems and syngas utilization make them energy-efficient and cost-effective. Ideal for industries like agriculture, construction, and energy, these furnaces produce high-quality charcoal, biochar, and activated carbon. Investing in a Continuous Carbonization Furnace means boosting productivity, cutting costs, and supporting eco-friendly practices.

Conclusion

In summary, a Continuous Carbonization Furnace is a vital tool for transforming organic materials into carbon-rich products. The carbonization process is simple, efficient, and eco-friendly. By investing in a Carbonization Furnace machine, you can enhance your production capabilities while contributing to a greener planet.

We’d love to hear your thoughts! Leave a comment below or share this blog on your social media platforms to help others learn about the benefits of carbonization furnaces.