The charcoal briquette business has gained significant attention in recent years due to the growing demand for sustainable and eco-friendly fuel sources. But is it truly profitable? In this blog, we will objectively analyze the profitability of the charcoal briquette business, explain how charcoal briquettes are produced using a charcoal briquette production line, and discuss the costs and return on investment (ROI) of setting up such a business. By the end, you’ll have a clear understanding of whether this venture is worth your investment.

Profitability Conditions for Charcoal Briquette Business

The profitability of a charcoal briquette business depends on several factors:

Market Demand: Charcoal briquettes are widely used for cooking, heating, and industrial purposes. In regions where traditional fuels are expensive or scarce, the demand for briquettes is high.

Industrial sector

Charcoal is in great demand in industry, especially in metallurgy and chemical industry. In metallurgy, charcoal is used as a reducing agent and fuel to help remove metal impurities and improve purity. It is also used to produce metals such as silicon and copper, and industrial silicon plants consume tens of thousands of charcoal blocks every year. Industry is the main consumer of charcoal.

Agriculture and animal husbandry

Charcoal plays a significant role in agriculture and animal husbandry. In agriculture, charcoal improves soil, increases fertility, and promotes crop growth. In animal husbandry, charcoal is used as a feed additive to improve animal digestion and health. Rational use of charcoal can improve production efficiency and reduce environmental impact.

Daily life

Charcoal is widely used in daily life. It is used for heating and cooking, providing a stable and efficient heat source. Charcoal can also purify air and water quality, and absorb impurities and harmful substances. Today, charcoal has become an indispensable part of life.

Raw Material Availability: The business relies on affordable and abundant raw materials like wood waste, sawdust, and agricultural residues. Low-cost materials increase profit margins.

In many agricultural countries, a large amount of crop residues and forestry waste are generated, but the waste utilization rate is less than 20%, resulting in a large amount of waste of resources such as branches, sawdust, rice husks and bamboo. Wood pelletizing machines can effectively utilize waste resources. Through charcoal machines, these wastes can be converted into efficient new energy sources such as charcoal or charcoal blocks. This process not only saves energy, but also contributes to environmental protection.

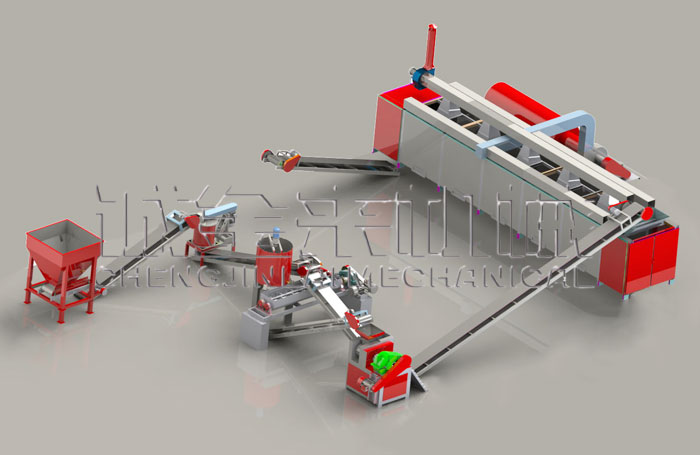

Production Efficiency: A well-designed charcoal briquette production line can significantly reduce operational costs and increase output, boosting profitability.As a professionals charcoal briquette machine manufacturer for more 15 year, we can provide you customize turnkey charcoal briquette prodcution line with affordable EXW price.

If these conditions are met, the charcoal briquette business can be highly profitable. However, success also depends on effective marketing, distribution, and cost management.

Charcoal Briquette Production Line Cost

Investmenting a charcoal briquette production line ranges from several thousand to hundreds of thousands of dollars.The charcoal briquette production line cost varies depending on the scale and complexity of the system.These costs include essential equipment like crushers, dryers, carbonization furnaces, briquette machines, and cooling systems. Additional expenses may include installation, training, and maintenance.

How Are Charcoal Briquettes Made?

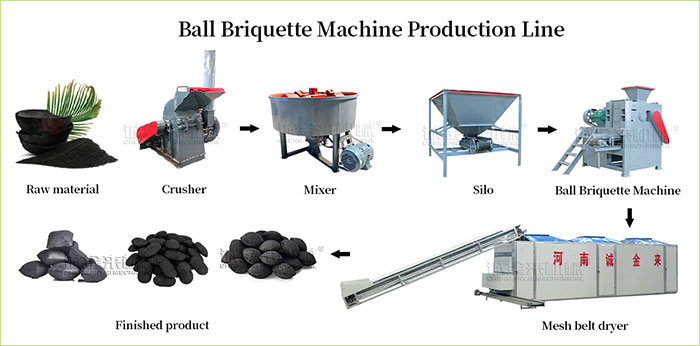

Charcoal briquettes are produced using a charcoal briquette production line. Here’s a step-by-step breakdown of the process:

- Material Preparation: Raw materials like wood chips, sawdust, or coconut shells are collected and crushed into small particles.

- Carbonization: The crushed materials are heated in a charcoal carbonization furnace at high temperatures (400°C–600°C) to remove moisture and volatile compounds. This process converts the biomass into charcoal.

- Crushing and Mixing: The charcoal is crushed into powder and mixed with a binder (e.g., starch or clay) to help the briquettes hold their shape.

- Briquetting: The mixture is fed into a briquette machine, which compresses it under high pressure to form uniform briquettes.

- Drying: The briquettes are dried to remove any remaining moisture, ensuring they are hard and durable.

The charcoal briquette production line is designed to be efficient, eco-friendly, and capable of producing high-quality briquettes in large quantities.

Return on Investment (ROI) Analysis

The ROI of a charcoal briquette business depends on factors like production capacity, market prices, and operational costs. Here’s an example:

- Initial investment: tens of thousands of dollars (small production line).

- Monthly Production: 200 tons of charcoal briquettes.

- Selling price: $300 per ton, the price of high-quality charcoal briquettes is even as high as $800-1200/ton

- Monthly Revenue: $60,000.

- Operating costs: $15,000 (raw materials, labor, utilities, etc., the charcoal briquettes manufacturing raw material cost is about $23~35/ton in China).

- Monthly Profit: tens of thousands of dollars

In this scenario, the payback period would be around 3–4 months, making the business highly profitable. However, actual ROI may vary based on local market conditions and operational efficiency.

Is Charcoal Briquette Business Profitable?

Yes, the charcoal briquette business can be highly profitable if managed effectively.

Affordable Investment: Starting a small briquette production line requires only a modest investment of tens of thousands of USD. This makes it an accessible option for small businesses and individuals, with minimal financial risk and pressure.

Easy Operation: The charcoal production process is straightforward, and the technology is simple to learn. With just two to three people, the entire production line can be efficiently managed, saving both time and labor while keeping production costs low.

High Profit Potential: The briquette production line uses low-cost raw materials like coal powder and carbon powder. The end product is a high-demand, premium coal rod, ensuring a strong return on investment.

Durable and Low Maintenance: The charcoal briquette machine features a simple design with minimal wear-prone parts. Even in the rare event of damage, repair costs are low, making it a long-term, cost-effective investment.

Versatile Production: The briquette line can process not only coal powder but also various carbon and iron powders. The molding size can be easily adjusted between 20-60mm, allowing flexibility to adapt to market demands and meet diverse customer needs.

If you’re considering investing in a charcoal briquette production line, now is the perfect time to take the first step. The demand for eco-friendly fuel is growing, and this business offers a chance to make a positive impact while earning significant profits.