Description

The Continuous Rotary Sawdust Carbonization Furnace is a high-efficiency machine used for the carbonization of relatively fluffy biomass materials such as sawdust and rice husks. It is ideal for industries that need to handle large volumes of raw materials, with a capacity of up to 20 tons per day. This furnace operates in a continuous mode, ensuring uninterrupted production and maximum output.

How Does A Continuous Carbonization Furnace Work?

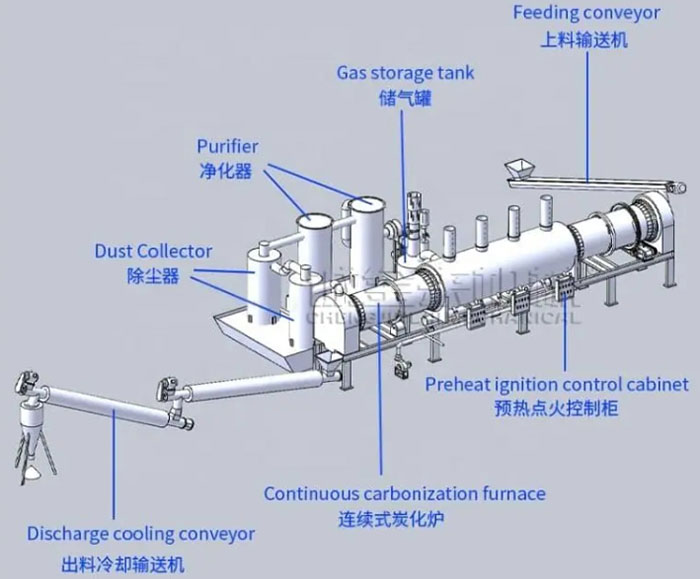

The rotary carbonization furnace is equipped with biomass gasification furnace, flue gas purifier, fan, self-distributed gas burner, carbonization furnace and other equipment.

The continuous carbonization furnace working principle is mainly to use pyrolysis technology to convert biomass such as sawdust into biochar, tar and combustible gas under high temperature without oxygen. Recycle the gas as fuel to improve energy efficiency, and finally collect biochar for reuse.

Initial stage: The biomass gasifier provides the initial ignition gas source

Carbonization process:

The material decomposes at a high temperature of 600℃ to produce combustible gas (CO/CH₄/H₂)

Gas treatment:

Separate wood tar and wood acid liquid through the flue gas purification system

Pure combustible gas enters the self-provisioning burner

Energy cycle:

The burner fully burns the gas

Generates heat to continuously heat the carbonization pipeline

System features:

Form a self-sufficient circulation heating system

Only initial ignition is required, and subsequent maintenance is maintained by self-produced gas

Here is the rice husk continous carbonization furnace youtube video testing for your customer in our factory for your reference!!

Continous Carbonization Furnace Features

The main carbonization furnace is made of 310S stainless steel, which has high strength, high temperature resistance, and is not easy to deform;

The main furnace of the carbonization furnace is a double-layer structure. The inner layer dries and pre-carbonizes the material, and the outer layer carbonizes the material at high temperature. The double-layer design improves thermal energy utilization and reduces floor space;

The traditional carbonization furnace burns one furnace and produces one furnace, and it takes a long time to cool down and produce carbon. The continuous carbonization furnace can produce carbon while feeding, and can carbonize continuously for 24 hours without stopping for cooling, saving heat energy and time;

Rotary Carbonization Furnace Parameter

| Model | BDTHL-1 | BDTHL-2 | BDTHL-3 |

| Pipe diameter(mm) | 800×1200 | 1000×1500 | 1200×1800 |

| Equipment capacity(kg/h) | 500-600 | 800-1000 | 1200-1500 |

| Furnace temperature(℃) | 350-850 | 350-850 | 350-850 |

| Carbonized pipe temperature(℃) | 500-800 | 500-800 | 500-800 |

Many industries have reported significant improvements after using the Continuous Carbonization Furnace. Test results show a 30% reduction in energy costs and a 25% increase in production efficiency. These outcomes demonstrate the furnace’s reliability and effectiveness.

Conclusion

The Continuous Carbonization Furnace is a game-changer for industries dealing with biomass materials like sawdust. With its high capacity, energy-efficient design, and proven performance, this furnace is a smart investment for sustainable production.

Ready to upgrade your operations?

👉 Contact us today to learn more about the Continuous Carbonization Furnace!

👉 Leave a message below, and our experts will assist you promptly!