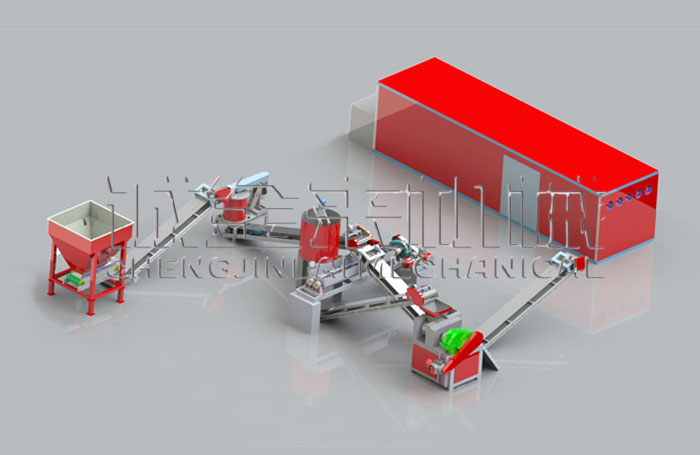

What is a Briquette Production Line?

A briquette production line is a series of machines and equipment that work together to produce briquettes. The process involves crushing, drying, compressing, and briquetting raw materials into uniform briquettes. These briquettes are easy to store, transport, and use as fuel.The briquette production line is highly versatile. It can process various materials, including wood, sawdust, agricultural waste, and charcoal powder. The line is designed to be efficient, eco-friendly, and cost-effective, making it a popular choice for businesses and industries.

The briquette production line is a complete system designed to transform raw biomass or waste materials into compact, high-density briquettes. These briquettes are widely used as fuel in industries, households, and for heating purposes. In this blog, we will explore the briquette production line in detail, including its components, working process, and benefits. We will also touch on the charcoal briquette making machine, a specialized version of this system.

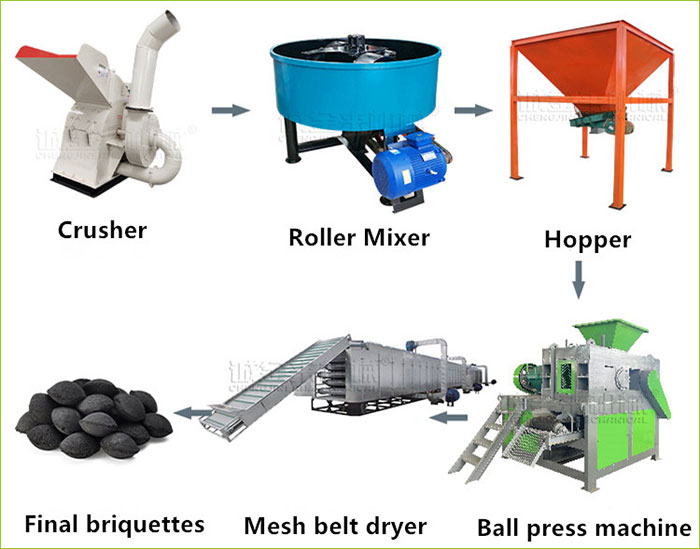

Briquette Production Line Key Components

A typical briquette production line consists of several key components:

- Crusher: Breaks down raw materials into smaller particles for easier processing.

- Dryer: Removes moisture from the materials to improve briquette quality.

- Briquette Machine: Compresses the materials into briquettes using high pressure.

- Cooling and Packaging System: Cools the briquettes and prepares them for storage or distribution.

Each component plays a crucial role in ensuring the efficiency and quality of the final product.

How Does a Briquette Production Line Work?

The working process of a briquette production line can be divided into several steps:

- Material Preparation: Raw materials are first crushed into small particles and dried to reduce moisture content.

- Briquetting: The prepared materials are fed into the briquette machine, where they are compressed into briquettes.

- Cooling and Packaging: The briquettes are cooled and then packaged for storage or distribution.

This process ensures that the briquettes are uniform in size, dense, and durable, making them ideal for use as fuel.

Briquette Production Line Benefits

Investing in a briquette making machinery offers numerous advantages:

- Waste Reduction: Converts biomass and waste materials into valuable fuel, reducing environmental pollution.

- Cost Savings: Provides a cheaper alternative to traditional fuels like coal and wood.

- Eco-Friendly: Produces clean-burning fuel with lower carbon emissions.

Additionally, the briquettes are easy to handle and store, making them a convenient fuel source for various applications.

Briquettes Applications

Briquettes produced by a briquette making machinery have a wide range of uses:

- Household Fuel: For cooking and heating in homes.

- Industrial Energy: As a fuel source in factories and power plants.

- Barbecue and Grilling: Popular for outdoor cooking due to their long burn time and consistent heat.

The versatility of briquettes makes them a valuable resource in both domestic and commercial settings.

Conclusion

The briquette production line is a powerful and eco-friendly solution for producing high-quality briquettes. It efficiently converts waste materials into valuable fuel, offering economic and environmental benefits. Whether for household use or industrial applications, this production line is a smart investment.

By understanding its components, working process, and maintenance needs, you can maximize its performance and contribute to a greener future. Explore your options today and take the first step toward sustainable energy production.