Description

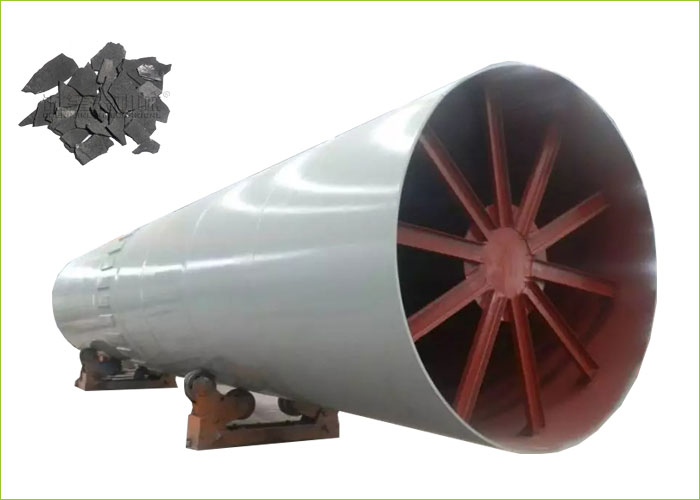

Activated Carbon Rotary Kiln plays a crucial role in the efficient production of high-quality activated carbon from coconut shells. As the demand for sustainable and eco-friendly carbonization solutions grows, an advanced rotary kiln with large capacity becomes essential for industries seeking high-performance production. Designed for continuous operation, this rotary kiln ensures uniform heating, optimized activation, and maximum yield. By leveraging precise temperature control and superior material handling, it enhances the adsorption properties of activated carbon, making it ideal for water purification, air filtration, and industrial applications. Investing in a high-capacity activated carbon rotary kiln not only improves production efficiency but also ensures consistency and quality in the final product.

Activated Carbon Rotary Kiln Features

The activated carbon rotary kiln stands out with these cutting-edge features:

Advanced Thermal Design: Ensures uniform heating up to 900-1100°C for complete carbonization of coconut shell material.

360-Degree Rotation: Promotes even heat distribution, eliminating cold spots and boosting carbon purity.

Emission Control System: Captures and recycles volatile gases, reducing pollution and fuel costs.

These features make it the most reliable and eco-friendly solution for industrial-scale activated carbon production.

Coconut Shell Rotary Kiln Advantages

Higher Efficiency: Processes coconut shell 30% faster with lower energy consumption.

Lower Maintenance: Robust stainless-steel construction resists corrosion and extends lifespan.

Better Product Quality: Produces activated carbon with larger surface area (700-1500 m²/g) for superior adsorption.

Rotary Kiln Performance Evidence

Case Study: A Philippine client increased annual revenue by $420,000 after switching to our kiln.

Lab Tests: Third-party analysis confirmed 98.5% carbon purity from coconut shell feedstock.

Industry Recognition: Awarded “Best Green Tech Equipment 2023” by Asian Manufacturing Association.

Choosing the right Activated Carbon Rotary Kiln is a critical decision for businesses aiming to scale up production while maintaining superior quality. A large-capacity rotary kiln designed for coconut shell activation ensures high output, energy efficiency, and optimal carbon properties. With its advanced thermal processing technology, this equipment maximizes carbon conversion rates and enhances product performance. Whether for industrial purification, environmental protection, or specialized applications, a high-quality activated carbon rotary kiln is the key to success. By investing in a reliable and efficient system, manufacturers can achieve long-term benefits, cost savings, and a competitive edge in the activated carbon market.